Your shopping cart doesn't have any products yet!

Description

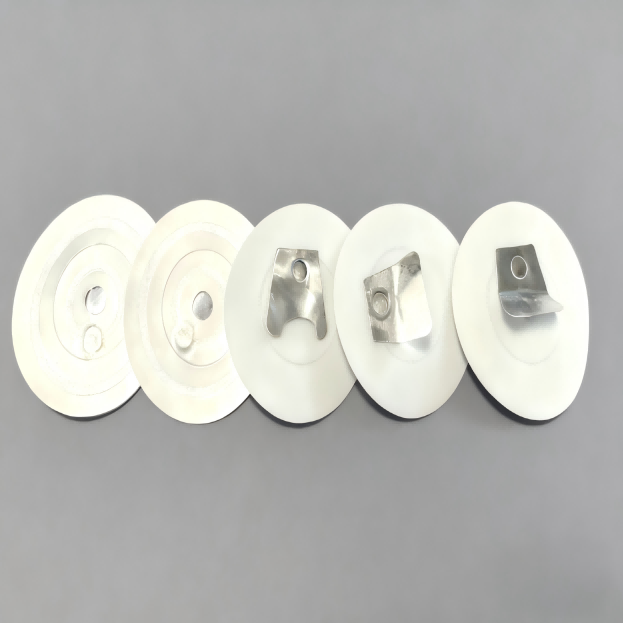

The PE Aluminum Foil Venting Liner provides excellent pressure balance and moisture protection for bottled products.

It is widely used in packaging for pesticides, liquid fertilizers, disinfectants, and pharmaceutical formulations, where high sealing performance and stability are required.

The built-in controlled venting system effectively balances internal and external pressure, preventing bottle bulging, leakage, and liquid overflow caused by gas expansion or contraction—ensuring safe and reliable product storage and transportation.

1. Product Overview

The PE Aluminum Foil Venting Liner is specifically engineered for modern bottled product packaging,

offering an intelligent sealing solution that combines airtight protection, moisture resistance, and controlled breathability.

Constructed from high-quality polyethylene laminated with aluminum foil and PTFE micro-venting film,

this liner maintains optimal pressure equilibrium while preventing leakage or bottle deformation caused by gas expansion or contraction.

Its precision venting system allows air exchange while blocking liquids and moisture ingress,

ensuring stable performance under temperature fluctuations and transportation conditions.

Ideal for pesticides, liquid fertilizers, disinfectants, pharmaceutical formulations,

surfactant-based liquids, and various additive products,

this liner provides dependable protection and long-lasting freshness throughout the supply chain.

2. Technical Features

Anti-bulging and leak-proof with automatic venting

Waterproof and breathable micro-vent membrane

Excellent chemical and oxidation resistance

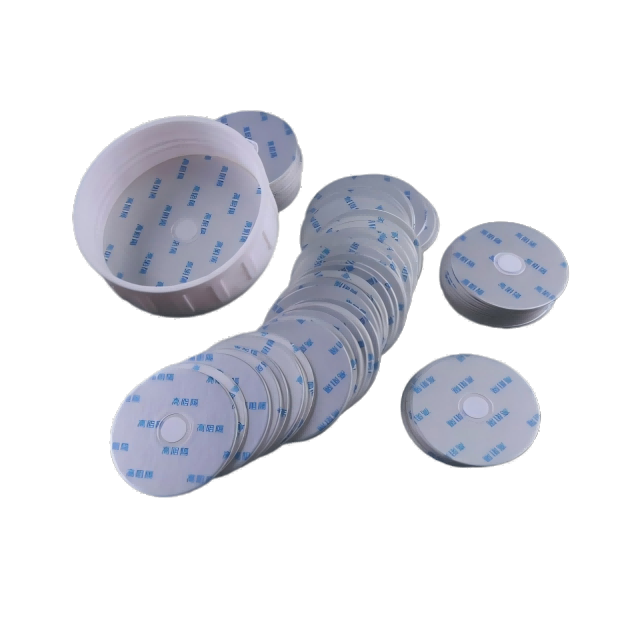

Compatible with PE, PET, HDPE, and PP containers

Customizable vent rate, thickness, and logo printing

3. Application Areas

Suitable for gas-generating or moisture-sensitive packaged products:

Pesticides, liquid fertilizers, herbicides, and fungicides

Surfactant-based detergents and household cleaners

Disinfectants, peroxides, and oxidizing chemicals

Pharmaceutical and laboratory formulations

Flavorings, cosmetics, and essential oils

4. Product Advantages

Maintains pressure balance to prevent bulging or leakage

Moisture and oxygen barrier extends shelf life

Improves packaging safety and brand image

Stable under transportation and temperature variation

OEM/ODM customization and private labeling available

4. Company Strength

Over 10 years of experience in liner manufacturing

Automated composite film production lines

ISO-certified quality control system

Exported to 40+ countries worldwide

One-stop service: design → sample → mass production → logistics