Your shopping cart doesn't have any products yet!

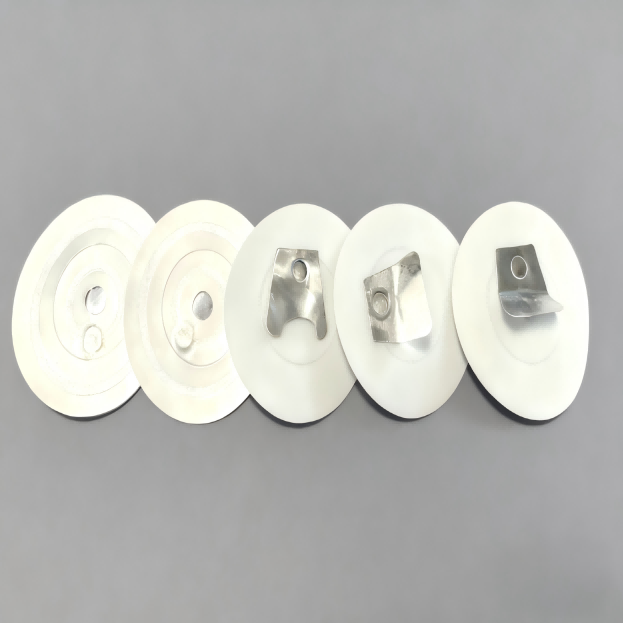

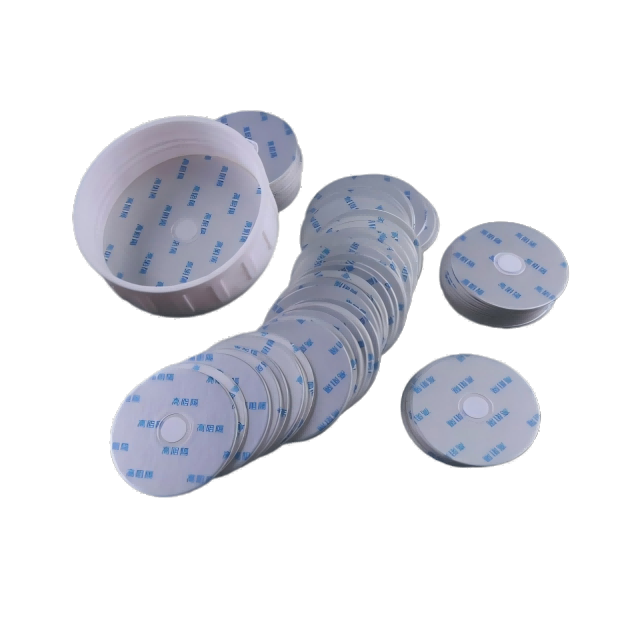

56.5 PE Aluminum Foil Venting Liner

Application: aluminum foil venting liner

PE Aluminum Foil Venting Liner

The PE Aluminum Foil Venting Liner is a functional sealing component that combines a waterproof venting membrane with a foam PE liner, bonded together through ultrasonic welding or hot-melt technology.

This integrated design ensures pressure equilibrium between the inside and outside of the container, effectively preventing deformation, sagging, or bulging during storage and transportation.

Working Principle

For perforated container lids:

The gas inside the container passes through the PE venting liner and escapes via the perforations on the lid, while the venting membrane prevents liquids, vapors, and particles from entering the packaging.

The foam PE venting liner continuously balances internal and external pressure differences, avoiding container distortion or leakage.For non-perforated container lids:

The gas moves through the PE aluminum foil venting gasket, reaching the space above the venting membrane, and then escapes through the threaded area of the container lid.

Meanwhile, the venting membrane provides effective protection against the ingress of liquids and particles.

The foam PE venting gasket maintains a stable internal environment by continuously equalizing pressure differences.

Customization

The Aluminum Foil Venting Liner can be fully customized according to customer requirements, including:

Size and thickness

Venting rate and membrane type

Printing or logo marking

Compatibility with various bottle neck sizes and closure designs

Key Benefits

Reliable air exchange with no liquid leakage

Prevents bottle swelling, sagging, or deformation

Excellent moisture and contamination resistance

Suitable for a wide range of chemical, agricultural, and cosmetic products