Your shopping cart doesn't have any products yet!

Packaging Applications of Waterproof Breathable Membranes: Integrated Technologies and Solutions

Waterproof breathable membranes (typically referring to ePTFE - expanded polytetrafluoroethylene membranes) are high-tech polymer films containing billions of microscopic pores per square inch. These pores allow gas molecules to pass freely but effectively block liquid water, oil, dust, and other contaminants based on physical effects like surface tension. This characteristic of "Allowing Air Passage While Blocking Water" makes them a key functional material for enhancing the performance of modern packaging.

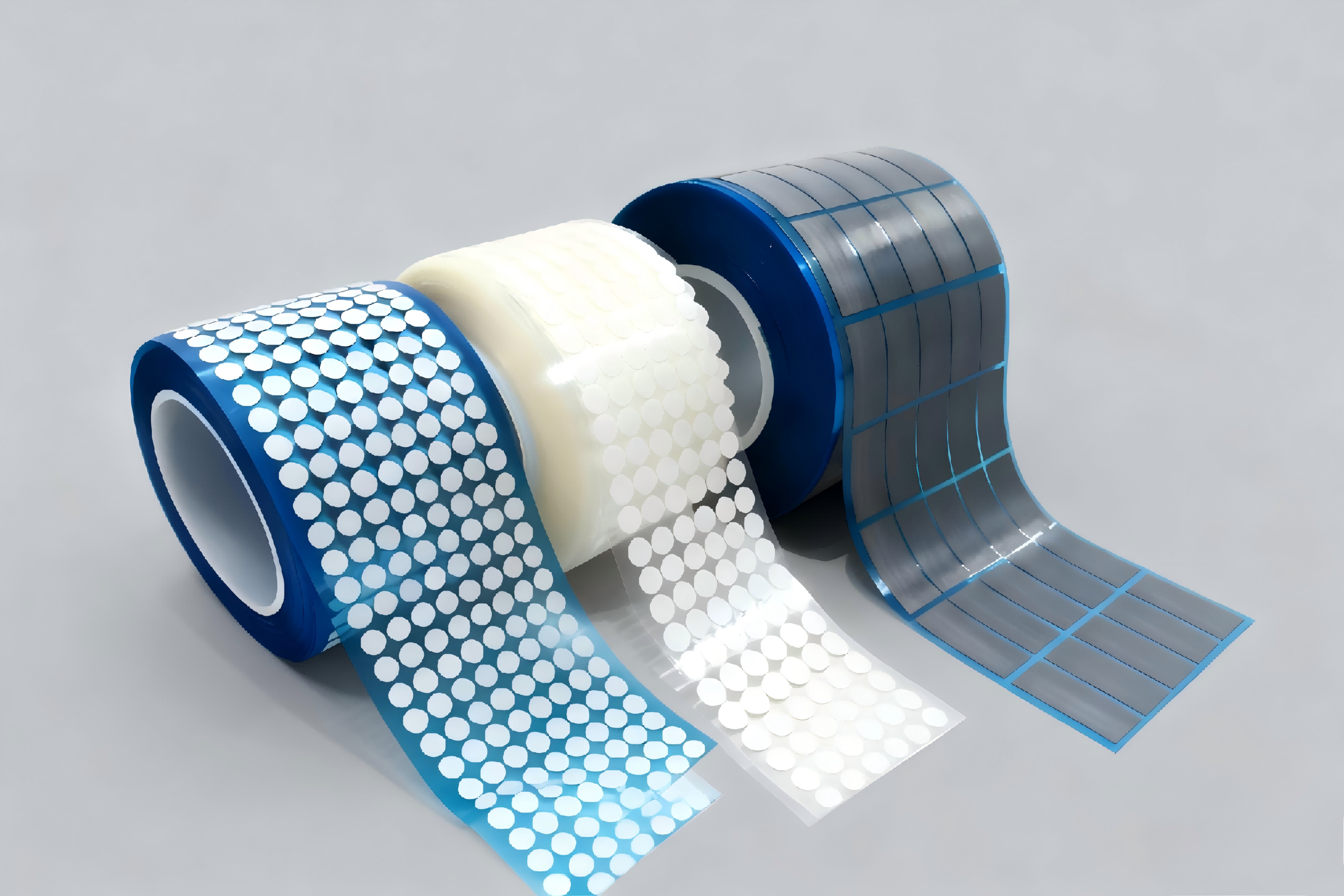

They can either be manufactured as standalone components like vent plugs or vent valves mounted on packaging, or directly integrated into the packaging material itself via heat sealing, high-frequency welding, or adhesive bonding, creating a "breathable" packaging system.

I. Core Functional Value

Pressure Equalization & Packaging Integrity Protection

Solves pressure differentials between the inside and outside of packaging caused by temperature changes, altitude variations, or gas generation from contents. Prevents: Packaging bulging, collapse, bursting, or vacuum lock, ensuring an upright appearance and facilitating stacking and transport.

Barrier Against External Contamination & Content Protection

While allowing air circulation, it forms an effective physical barrier. Blocks: Liquid water, moisture, salt spray, dust, bacteria, and other microorganisms, protecting products from humidity, contamination, and corrosion.

Timely Venting & Risk Mitigation

Provides a controlled escape path for gases generated inside the packaging (e.g., sterilization gases, chemical vapors, battery off-gassing). Avoids: Seal failure, leakage, or safety risks due to pressure buildup.

II. Integrated Application Forms & Case Studies

Specific Scenario Explanations:

Standard Component Applications

Vent Plugs for Chemical/Pharmaceutical Bottles: Screwed or pressed into bottle caps, becoming part of the packaging, providing pressure equalization for volatile or temperature-sensitive products. Protective Vent Caps for Electronic Devices: Used on packaging for electronic equipment requiring outdoor protection, ensuring internal dryness.

Direct Integration into Packaging Material Applications

Sterilization Bags for Medical Devices: Laminating the breathable membrane with materials like Tyvek allows toxic ethylene oxide gas to be vented after sterilization while maintaining internal sterility. Moisture Barrier Bags for Electronics: Integrating a vent valve onto anti-static aluminum foil bags balances atmospheric pressure changes during transit in a sealed environment, preventing internal condensation and protecting delicate components. Modified Atmosphere Packaging for Food: Using functional breathable membranes in specific areas of the packaging precisely regulates gas exchange between the inside and outside, maintaining the low-oxygen, high-carbon dioxide environment required for fruits and vegetables, extending shelf life.

III. Selection and Integration Considerations

When selecting a waterproof breathable membrane solution for packaging applications, the following factors must be comprehensively considered:

Performance Parameters

Airflow Rate/Permeability: Meets requirements for pressure equalization speed. Waterproof Rating: e.g., IPX7, IPX8, ensuring it can withstand expected liquid exposure environments. Burst Pressure: The maximum pressure differential the membrane can withstand without failure.

Material Compatibility

Chemical Compatibility: Must resist degradation from packaged contents (e.g., solvents, acids, alkalis, oils). Compatibility with Packaging Materials: Ensure reliable bonding with substrates (e.g., plastics, metals, composite materials).

Process & Regulations

Integration Process: Select an integration method (welding, adhesion, in-mold, etc.) compatible with existing production lines. Regulatory Certifications: For food, pharmaceutical, and medical device packaging, materials must comply with relevant regulations (e.g., FDA, USP Class VI, EU 1935/2004, REACH).

Summary

The waterproof breathable membrane is an "enabler" of intelligent packaging design. It transcends the traditional functions of mere "containment" and "isolation," introducing an intelligent dimension of "controlled exchange." Whether as a standalone component or integrated into the packaging material itself, it passively and reliably significantly enhances packaging reliability, safety, and product protection capabilities, providing key solutions for challenges across different industries and complex supply chains.