您的购物车还没有商品!

Packaging Applications of Vent Plugs: A Comprehensive Pressure Management Solution

A vent plug is a miniature engineered component that integrates a micro-porous venting membrane (typically ePTFE). Operating on the physical principle of "Allows Air to Pass, Blocks Liquids," it serves as an essential "intelligent breather" in modern packaging, widely used in sealed packaging that requires pressure equalization and contamination prevention.

Its core value lies in: Passively maintaining the pressure balance between the inside and outside of the packaging, thereby protecting packaging integrity and enhancing product quality and safety.

I. Three Core Packaging Problems Solved by Vent Plugs

Preventing Packaging Deformation

Problem: During air freight (altitude changes), land transport (crossing areas with temperature variations), or storage with ambient temperature fluctuations, the air inside the packaging expands and contracts, creating positive or negative pressure. Result: Positive pressure causes packaging to bulge or seals to burst; negative pressure causes packaging to collapse or deform. Vent Plug Solution: Instantly equalizes air pressure, maintaining the packaging's upright and aesthetically pleasing shape.

Preventing Liquid Leakage and Contamination

Problem: Packaging exposed to humid, dusty, or wash-down environments is susceptible to ingress of external contaminants. Result: Product moisture damage, spoilage, contamination, or damage to internal electronic components. Vent Plug Solution: The micro-pores of the vent membrane effectively block liquid water, moisture, dust, and bacteria, while allowing air to pass through.

Releasing Internal Gases

Problem: Some products (e.g., batteries, chemicals) slowly release gases, or residual gases remain after sterilization (e.g., Ethylene Oxide). Result: Packaging slowly bulges, presenting potential risks. Vent Plug Solution: Allows these微量 gases to safely vent, preventing pressure build-up.

II. Core Application Industries and Specific Cases

Liquid Packaging Industry

Chemical/Pesticide Bottles: Prevents drum bulging and leakage caused by temperature changes or product volatilization, ensuring transport safety. Food Sauce Bottles: Prevents bottle collapse after hot-filling and subsequent cooling. Personal Care Products: Maintains the shape of shampoo and body wash bottles, preventing difficulty in squeezing due to negative pressure.

Electronics and Automotive Industry

Automotive Headlights: Balances pressure inside and outside the lamp to prevent condensation from sudden temperature changes, ensuring clear illumination and safety. Outdoor Surveillance Equipment: Prevents condensation inside the housing, protecting delicate circuits. Drones/Action Cameras: Manages temperature differences between high altitude and ground level, protecting electronics.

Medical and Food Packaging

Sterile Medical Device Packaging: Vents residual toxic sterilant gas (e.g., EtO) after sterilization, while maintaining internal sterility. Modified Atmosphere Food Packaging: In specific applications, helps regulate the gas composition inside the package to extend shelf life.

Industrial and Consumer Goods

Products containing Lithium Batteries: Vents微量 gases produced by batteries during charging/discharging or anomalies, preventing packaging from swelling and rupturing. Precision Instruments: Protects equipment from condensation damage in high-humidity environments like shipping containers.

III. How to Select a Vent Plug for Your Packaging?

Selecting the right vent plug is crucial to ensure its effectiveness.

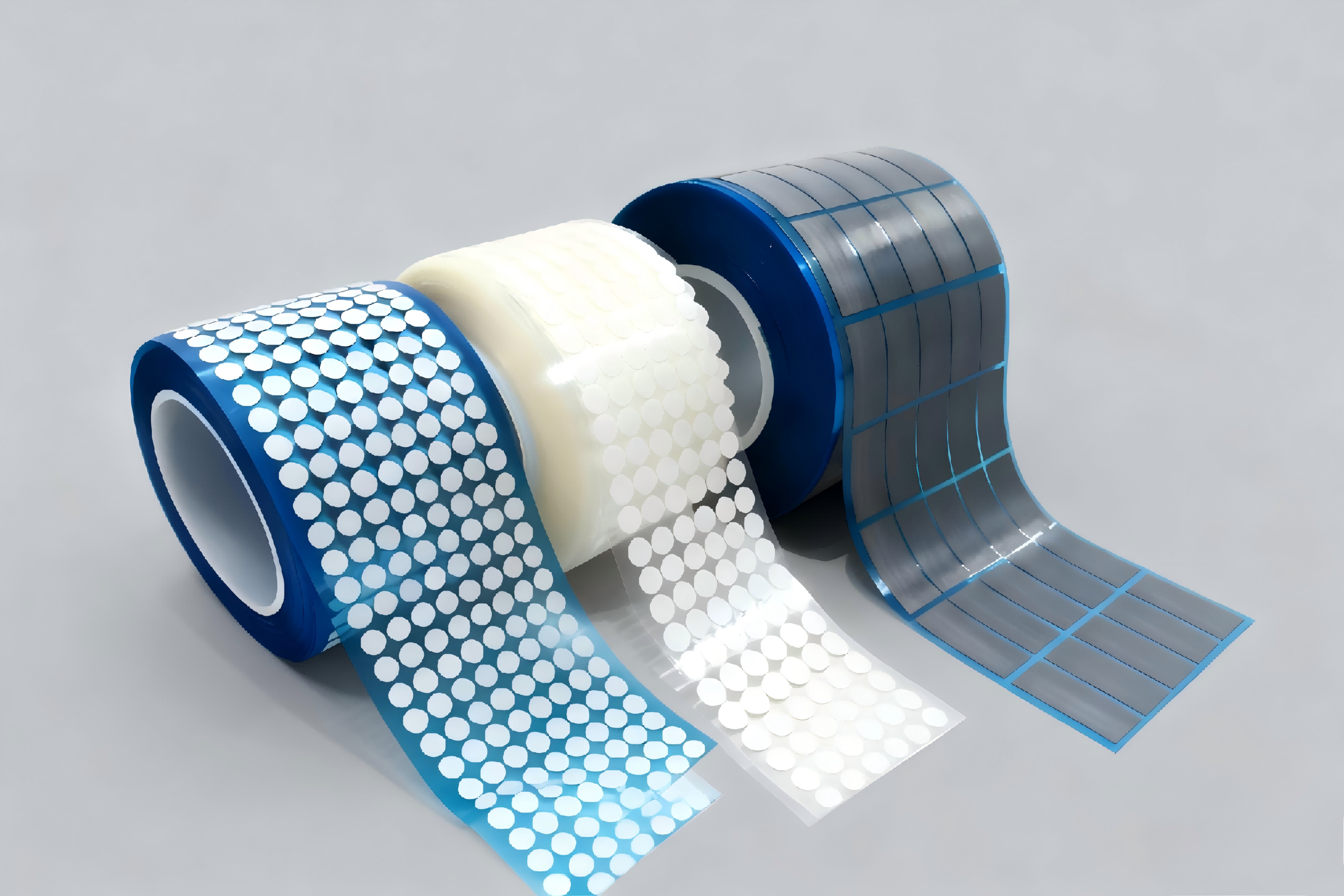

Determine Airflow Rate: Calculate based on the volume of the packaged contents and the maximum expected pressure differential. Define Protection Rating: Select the appropriate rating like IP67 (waterproof immersion) or IP65 (water jet protection) based on storage and transport environments. Check Chemical Compatibility: Ensure the vent plug materials resist the chemical nature of the packaged product (e.g., solvents, acids, alkalis, oils). Choose Installation Method: Adhesive-Backed: Simplest, sticks directly to the packaging surface. Snap-In / Screw-In: More secure, requires a hole in the packaging for fixation. Weld-In: Offers the strongest seal, suitable for plastic packaging.

Consider Size: Choose a size appropriate for the packaging design while meeting performance requirements.

Summary

Though small, the vent plug is a "guardian" in modern packaging design. Through its ingenious physical design, it provides a passive, reliable, and low-cost solution to the core challenges of sealed packaging in dynamic environments—pressure equalization and contamination protection. Whether ensuring the safe transport of a pesticide bottle or protecting the clear vision of a headlight on a rainy night, the vent plug plays an indispensable role behind the scenes.